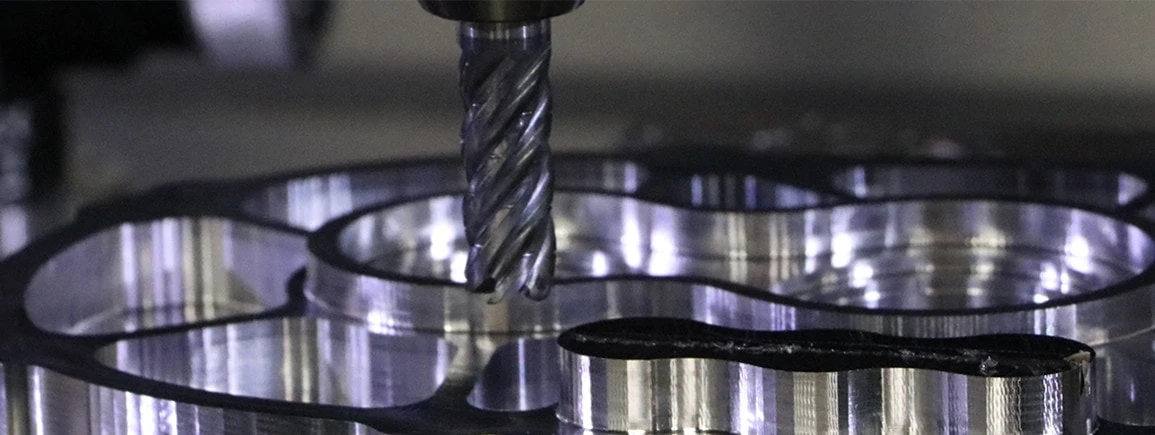

What is Precision Machining?

Precision machining is the process of removing material from a workpiece to create parts with specific dimensions and surface finishes. Using CNC (Computer Numerical Control) machines, we transform forged or cast steel components into finished parts that meet your exact specifications. Machining enables us to achieve tight tolerances, complex geometries, and smooth surface finishes required for critical applications.

Our Machining Capabilities

- CNC Turning: Precision turning of shafts, pins, bushings, and cylindrical components up to 1000mm diameter

- CNC Milling: Complex milling operations for flanges, blocks, plates, and custom geometries

- Drilling & Boring: Accurate hole making and enlarging operations with tight positional tolerances

- Thread Cutting: Internal and external threads to various standards (metric, UNC, UNF, BSW)

- Surface Grinding: Achieving precise flatness and smooth surface finishes

- Cylindrical Grinding: For high-precision shafts and cylindrical components

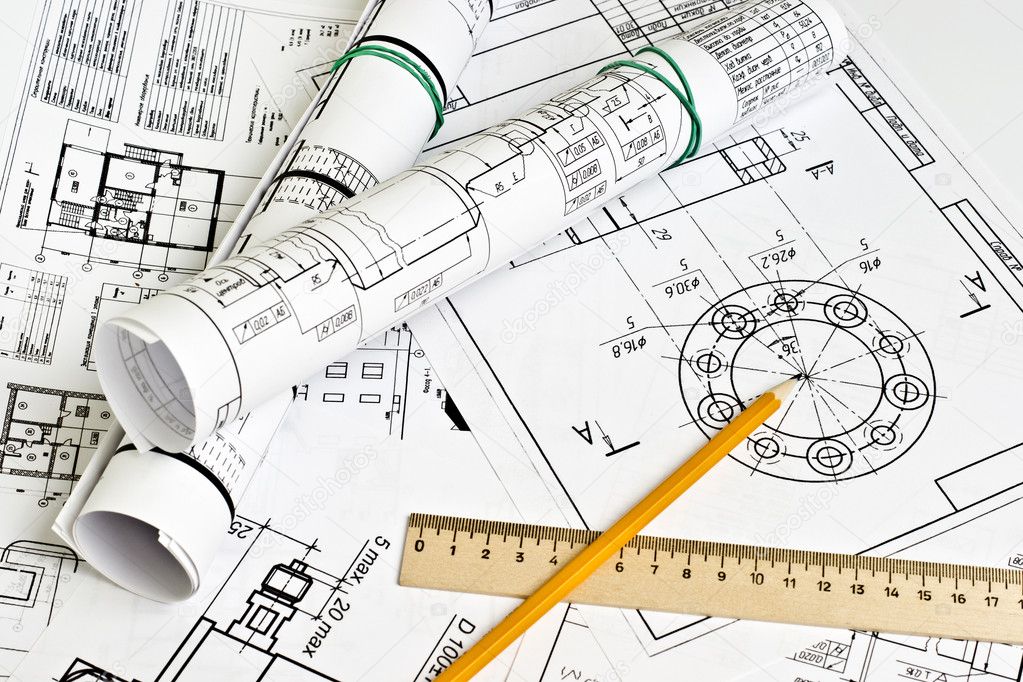

Machining from Your Drawings

We work directly from your technical drawings to produce precision machined components.

Service Options:

Proof Machined: Basic machining operations to establish primary dimensions and features. Suitable for components that will undergo further machining by the customer or require rough dimensional accuracy.

Fully Machined: Complete machining to final dimensions with all features including keyways, splines, threads, and holes. Parts are ready for assembly with finished surface quality and tight tolerances.

Tolerance Capabilities:

- Standard machining tolerances: ±0.1mm to ±0.5mm

- Precision machining tolerances: ±0.01mm to ±0.05mm

- Surface finish: Ra 0.8 to Ra 12.5 μm depending on requirements

- Positional tolerance: Within ±0.02mm for critical features

Materials We Machine

We have extensive experience machining all types of steel:

- Carbon Steel: From soft low-carbon grades to hardened high-carbon steels

- Alloy Steel: Including hardened and tempered alloy steels like 4140, 4340, EN24

- Stainless Steel: Austenitic (304, 316), ferritic, martensitic, and duplex grades

- Tool Steel: Hardened tool steels for demanding applications

Quality Assurance

Every machined component undergoes rigorous inspection:

- CMM (Coordinate Measuring Machine) inspection for complex geometries

- Vernier calipers, micrometers, and height gauges for dimensional verification

- Surface roughness measurement

- Thread gauging and verification

- First article inspection reports (FAIR) when required

Applications

- Automotive components (shafts, gears, hubs, flanges)

- Industrial machinery parts

- Oil & gas equipment components

- Aerospace precision parts

- Power transmission components

- Custom machinery components

Why Choose Azzaron for Machining?

- State-of-the-art CNC machining centers

- Experienced machinists and programmers

- Capability to machine from customer drawings

- In-house inspection and quality control

- Flexible capacity from prototype to production runs

- Competitive pricing with consistent quality