What is Forging?

Forging is a manufacturing process that shapes metal through controlled deformation using compressive forces. The metal is heated to a malleable state and then pressed, hammered, or rolled into the desired shape. This process improves the mechanical properties of steel, creating components with superior strength, toughness, and structural integrity compared to castings or machined parts.

Our Forging Capabilities

- Hot Forging: We forge carbon, alloy, and stainless steel at elevated temperatures for optimal material flow and grain structure

- Open Die Forging: For large components like shafts, blocks, rings, and custom shapes

- Closed Die Forging: For precision components requiring tight tolerances and complex geometries

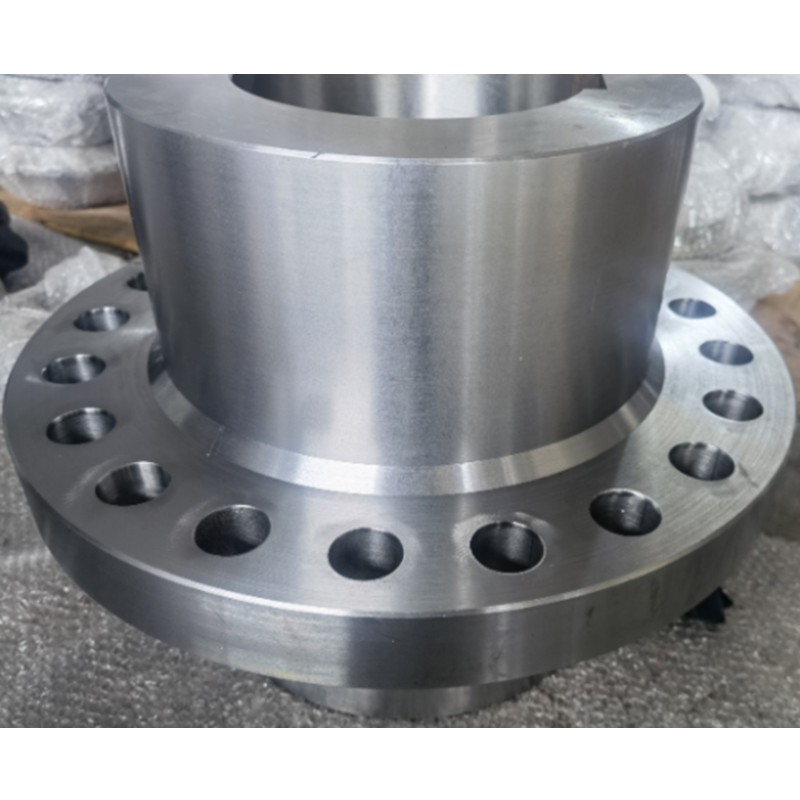

- Ring Rolling: Seamless rolled rings for flanges, bearings, and gears

- Weight Range: From small components under 1 kg to large forgings over 500 kg

Custom Forging Process

Azzaron Overseas works directly from your technical drawings to produce custom forged components.

Our Process:

1. Design Review: Submit your technical drawings, specifications, and material requirements. Our engineering team reviews your design for forgeability and suggests optimizations if needed.

2. Material Selection: We help you select the optimal steel grade (carbon, alloy, or stainless) based on your application requirements for strength, corrosion resistance, and operating conditions.

3. Tooling & Setup: For closed die forging, we design and manufacture dies. For open die forging, we program the forging sequence.

4. Forging: Steel is heated to the appropriate forging temperature and shaped through controlled deformation. Multiple heats and stages may be required for complex geometries.

5. Heat Treatment: Components undergo normalizing, annealing, or quenching and tempering as specified to achieve required mechanical properties.

6. Quality Control: Dimensional inspection, ultrasonic testing, mechanical testing, and material certification ensure every forging meets your specifications.

Materials We Forge

- Carbon Steel: AISI 1018, 1020, 1045, 1050, 1060, EN8, EN9, EN19, C45, C60

- Alloy Steel: AISI 4140, 4340, EN24, 42CrMo4, 34CrNiMo6, SAE 8620

- Stainless Steel: 304, 304L, 316, 316L, 321, 347, 410, 420, 17-4PH

- Tool Steel: H11, H13, EN31, 52100

Applications

Our forged components serve critical applications across industries:

- Automotive and heavy vehicle components (crankshafts, connecting rods, gears)

- Oil & gas equipment (flanges, valves, wellhead components)

- Power generation (turbine shafts, generator components)

- Aerospace components (landing gear parts, structural fittings)

- Industrial machinery (press frames, mill housings, large gears)

- Mining equipment (crusher components, excavator parts)

- Agricultural machinery (tractor components, implement parts)

Why Choose Azzaron for Forging?

- Decades of experience forging components for demanding applications

- Capability to forge from customer drawings and specifications

- Full traceability of materials from melt to final component

- In-house heat treatment and testing facilities

- Compliance with international standards (ASTM, DIN, EN, JIS)

- Competitive pricing with consistent quality and delivery